We took a break from posting on this blog to purchase and install a new engine. We knew there was a risk that the rebuild of our original engine would fail, and it did. After asking about the scrap value (we were offered about $9 if we hauled it to the scrap yard) we decided to donate our old M25 as a teaching engine. Hopefully, others will learn from our misfortune.

We decided to order a shiny new Beta 25. It’s built on a Kubota engine block, just like our old M25, and the mounts are designed to make it a (fairly) close replacement. After spending a few months in the queue, our engine was flown from England to California and trucked right to our marina parking lot.

Then we had a new engine and an empty engine compartment.

Of course, the Beta 25 sits about an inch lower than our old M25, so we had to make spacers to lift it up. We also had to drill new holes for the mounts, which meant fabricating a drill jig. This required lifting the engine out and setting it back down several times to get it right.

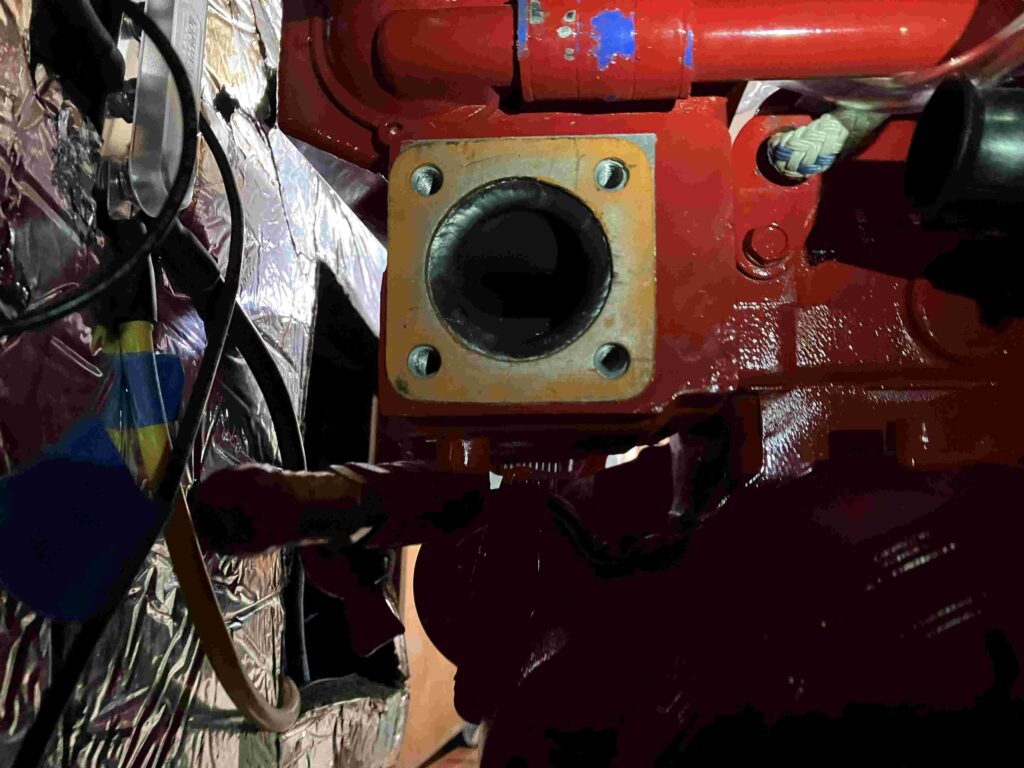

Naturally, the size and shape of the exhaust differed between old and new engines, so we had to hire an exhaust shop to modify our exhaust elbow.

When we connected the transmission shift lever, we discovered that it was backwards: push forward to shift into reverse, and vice versa. All you have to do is spin the lever 180 degrees on the transmission, but of course there wasn’t enough space. The solution is to make a lever to reverse the lever (aka a bell crank), which we bolted onto the new bracket.

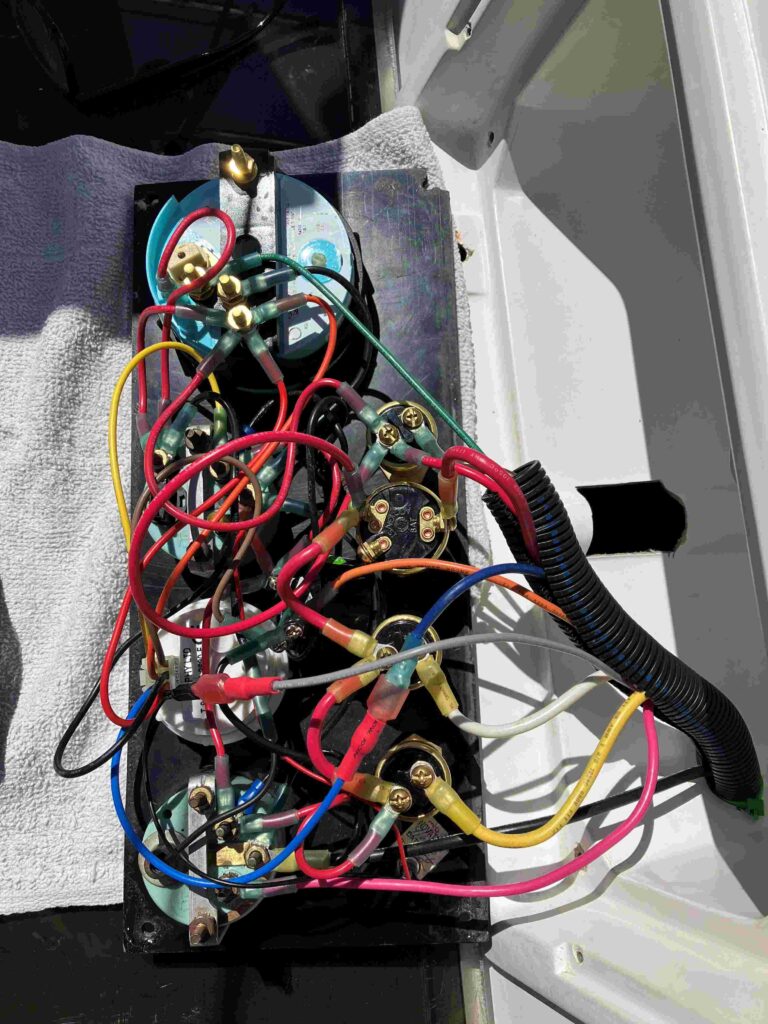

Due to a few differences between the old M25 and the new Beta 25, we also had to rebuild the cockpit instrument panel, again. We took advantage of the opportunity to install a new tachometer with an hour meter, starting at 0 hours.

After all that, just add oil, coolant, and diesel (and a bunch of other annoying parts and pieces), and it starts.